Large laboratory nitrogen generator process and purity requirements

2021-05-23

The large-scale laboratory nitrogen generator uses a low-pressure process to extract pure oxygen and pure nitrogen from the air by deep freezing and rectification, that is, to liquefy the air by the principle of a turboexpander refrigeration cycle, according to liquid oxygen and liquid nitrogen. The boiling point is different, and secondary rectification is carried out in the fractionation column to obtain 99.6% purity oxygen and 99.99% purity nitrogen. Partial liquid oxygen, liquid nitrogen and medical oxygen can also be obtained by changing operations as needed.

Introduction to the process flow of a large laboratory nitrogen generator:

1. Air compressor: The air is compressed by air compressor to 0.5Mpa-0.7Mpa.

2. Pre-cooling: The air is pre-cooled to 5 °C - 10 °C in the pre-cooling unit, and the water is separated.

3. Purification: The air removes residual moisture, carbon dioxide and hydrocarbons from the

Molecular Sieve purification gas.

4. Air expansion: The air expands and cools in the expander to provide the required cooling capacity.

5. Heat exchange: The air is exchanged with the refluxing oxygen, nitrogen, and nitrogen in the main heat exchanger of the fractionation tower, and is reheated to the ambient temperature by the cooled sewage nitrogen.

6. Too cold: The night sky and liquid nitrogen are too cold in the subcooler by nitrogen and nitrogen.

Rectification: The air is rectified and separated in the lower column, and the product nitrogen is obtained at the top of the upper column, which is obtained in the upper column.

Nitrogen gas purity requirements

It can only be filled with nitrogen. At an ambient temperature of 20 °C / 68 °F, the standard pressure of the accumulator in Hebei nitrogen generator is 55kg/cm2/780PSL, and nitrogen should not be overfilled. Precautions for charging the accumulator in the psa nitrogen generator When filling the nitrogen, it is necessary to use a pressure gauge, a liquid nitrogen nitrogen generator, and when filling the accumulator with nitrogen, make sure that the accumulator body is intact and that the plug is fully tightened. . Confirm that the switch and relief valve of the pressure gauge are completely closed; after unscrewing the plug on the accumulator, tighten the inflation valve; confirm that the o-ring on the coupling is installed and plug the accumulator After removing it, connect it to the three-way valve and tighten the nut.

The growing demand for carbon molecular sieves will further fuel the industry, and the industry will become well known in an unfamiliar industry in the next few years. Secondly, with the increase of application depth, the requirements for nitrogen production, nitrogen recovery rate, bulk density and compressive strength of carbon molecular sieves are getting higher and higher. Laboratory nitrogen generators will further improve product performance indicators. The general trend of future development of an industry.

Therefore, microelectronic devices, biotechnology products and instruments have strict requirements on the purity of process gases. The requirements for nitrogen production in pharmaceutical production are used for potting of injection. The nitrogen produced by the nitrogen generator does not contain dust and heat. The purity of nitrogen required to produce nitrogen is 99% to 99.99%. Nitrogen is required in the production process. Maintain constant pressure supply to ensure normal operation of production.

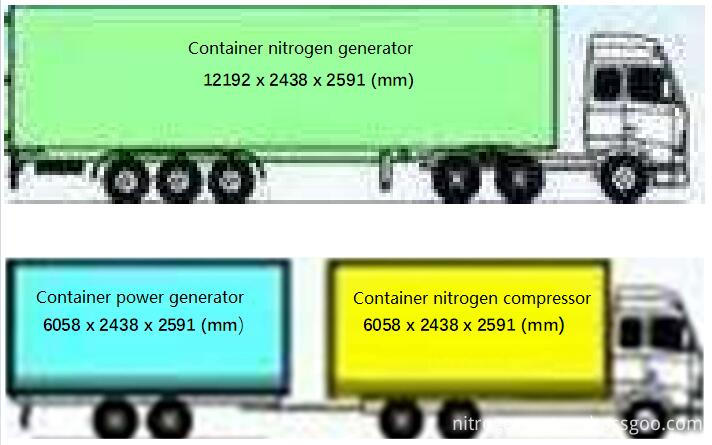

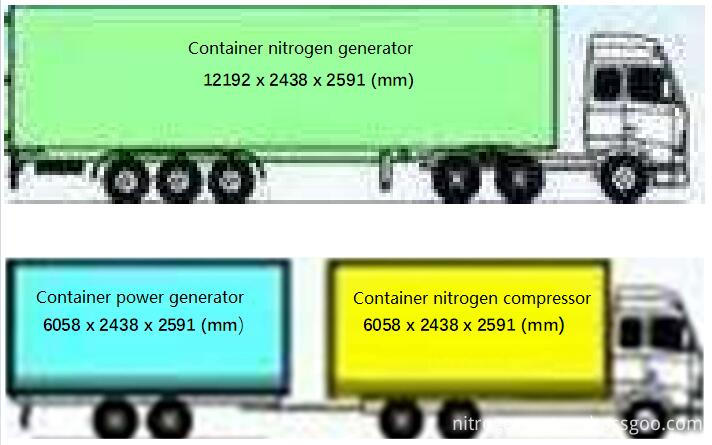

Outdoor Container all-in-one PSA Nitrogen Plant is the compact nitrogen generator designed for customers who need

all-in-one solution. For some customers, their site area is limited, and

they prefer one container nitrogen generator every part inculded. Some

cusotmers need the nitrogen generator have low noise, rain proof, this

container type nitrogen plant is the ideal solution.

Air compressor suction

air from atmosphere,then the compressed air enters one air treatment

part to get rid of dust,water, dust,etc, achieving clean and dry

compressed air. This air treatment part mainly consists of three

filters, one refrigerant dryer and one activated carbon oil remover.

After treatment, the compressed air enters one air tank to make air

stable. Then the compressed air enters PSA nitrogen/oxygen separator.

After passing through this nitrogen/oxygen separator part, nitrogen is

collected. The produced nitrogen enters one nitrogen buffer tank. At the

outlet of nitrogen buffer tank, stable and qualified nitrogen is sent

to using point.

Below is a container nitrogen generator with 98% purity, 1200 Nm3/hr flow rate.

Container nitrogen generator technical specification

Flow rate: 5-2000 Nm3/hr

Purity: 95-99.999%

Outlet perssure: 5-200 bars(72.5-2900 psi)

Container Nitrogen Generator,

Container Psa Nitrogen Generator,

Containerized Nitrogen N2 Generator,

Container Nitrogen Gas GeneratorArtificial Graphite & Active Carbon Co., Ltd. http://www.gammagases.com